The inspiration for this blog comes from a friend who implemented an ERP. He owns and manages an Engineering goods company and like most them his company struggles with large inventory of raw materials, intermediate products and finished goods. The routing of material in manufacturing process is equally complex with continuous back and forth movement of material for processing. An item can be classified as Raw material, Semi Finished Good or Finished Good based on where it is headed.

The instinctive reaction of the friend was to start with production followed by inventory module and then Finance and Accounts. Nothing wrong with it provided ERP can be implemented within that financial year or it may lead to several problems. For one, half the information needed for finalization of books of accounts would come from ERP and the other half would come from Accounting software. The other problem is accounting for costs, matching payments to receipt of material. With GRNs/ MRNs being prepared in ERP, the three-way matching will have to be physical. The accountant will have to ensure that he has the latest copy of the purchase order or its modifications. Either way it increases company’s vulnerability to fraud ( https://mentorsunlocked.com/fraud-anecdotes-or-systems-weaknesses/ )

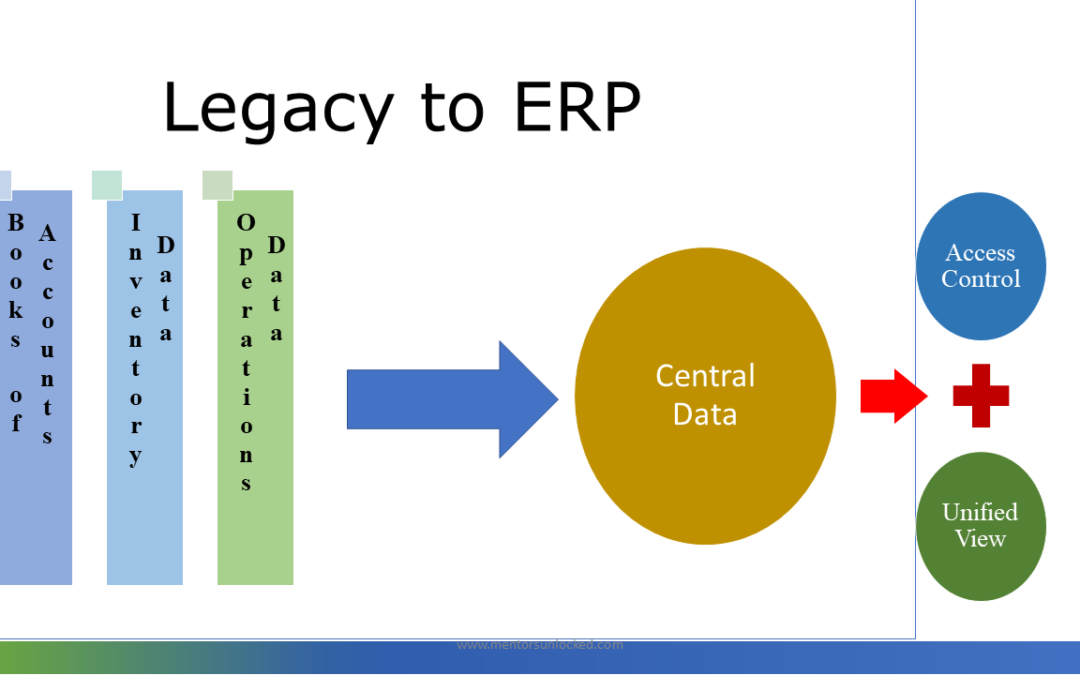

The friend would have done better had he first integrated inventory with finance and accounts and then moved to production, just like it is advised. He also gained this insight in hindsight. The biggest advantage would have been that it would have given the implementer a better idea or appreciation of his business besides giving implementer confidence given successful implementation of two modules. The implementer started with Production module and got lost in its complexities.

The problem of getting too deep into implementation of a module also increases risk of losing the bug picture. As a CEO, he should be focussed more on his information needs or data that he would need for analysis rather than grappling with nitty gritty of the modules or how the modules are going to interact with each other.

Our suggestions are

- Start design of systems with broader design. Something akin to a layout plan. Indicating the features that you would want in your ERP. These features could be specific to a module or may overlap over couple of more modules.

- A team of functional experts, either in house or from outside who understand business and are able to provide guidance and work out details with your ERP Implementor. The team would cost much less than your own time, which can be spent in managing day to day operations. At the end of the day, ERP cannot be a distraction, that takes the founder away from his bread-and-butter business.

- Let the team develop an action plan with milestones and deliverables. Break the project into a cycle of 20/30 days and let team come up with a deliverable at end of each cycle.

- Fix a timeline for review at the end of the cycle. Let the functional consultants or your project manager give you a presentation on what was achieved and demonstrate the software functionalities.

- Plan for next cycle and discuss it with the team.

Best of Luck .