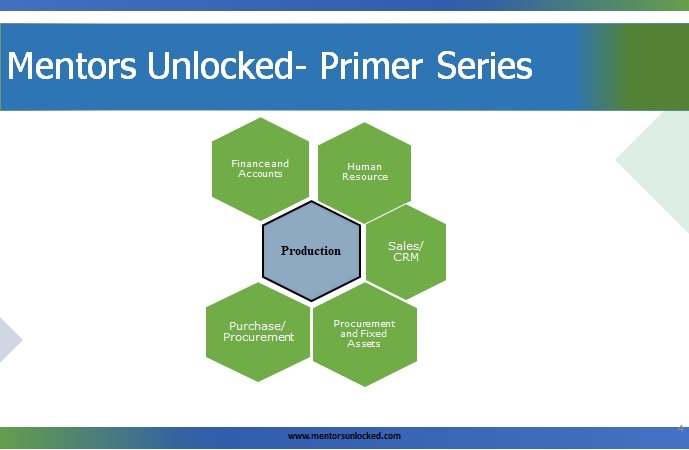

In our previous blogs (https://mentorsunlocked.com/mu-primer-series-1-basics-of-inventory-module-in-erp/ ; https://mentorsunlocked.com/mu-primer-series-1-basics-of-finance-and-accounts-module-in-erp/ ), (https://mentorsunlocked.com/mu-primer-series-1-basics-of-hr-module-in-erp/) we had talked about basics of Finance and Accounts module, HR and Inventory. In this blog, we will talk about essentials of Production module.

Most Small and Medium Enterprises (SMEs) struggle with their working capital. Unlike big businesses, they have limited avenues to raise funds at reasonable rates. It is important that they are able to synchronize their production, inventory and procurement to optimise their working capital requirements. This is one of the main reasons why MRP software became very popular. The heart of MRPs and their successor ERPs is production planning.

The ERPs cater to different types of industries and businesses. The policies, processes and practices in each business are different. That is why, ERP provides options to configure the software to meet with diverse needs of the business. For example, Inventory can be issued and valued on FIFO, LIFO or expiry first basis. Most ERPs provide for production plans to be developed based on “Made to Order” or ”Made to Stock” basis.

Planning processes in Production are iterative and inter-dependent on each other besides being function of Bills of Materials and availability of resources. Production planning is a function of capacity planning, Machine availability and available resources that includes trained labour and material. ERPs bring in efficiencies and accuracies in planning process. Most ERPs have ability to provide Capacity Planning, Route Planning and Machine Planning, Production Planning and Material Resource Planning using Bill of Material. Depending on the ERP, they may provide flexibility of tagging multiple BoMs with one product / product style or multiple products with same BoM. Some ERPs allow the machine operating costs to be incorporated in machine details such as cost of labour and utilities needed to operate the machine per hour or per piece. The actual costs can also be factored in thus making it easy to determine direct cost of production in comparison to the budgeted cost of production. The material consumption can be automated with budgeted quantities as per BoM or could be updated manually.

The companies follow multiple models for manufacturing. For example, some manufacturers produce everything in-house while there are others that sub-contract some processes while some also buy semi-finished goods. Similarly, the companies may also have stage wise production creating semi-finished goods that can be sold as products by themselves and finished goods. Most ERPs have flexibility to accommodate these. They support sub-contracting of processes and different practices such as accounting for sub-contracted processes as sale of material and purchase of material or as a sub-contract. The semi- finished goods can be transferred to finished goods stores and dispatched.

In India, most SMEs struggle with a work force that is not adept in documentation and filling. The workers may be literate but still struggle with filling forms and writing log books. In situations like these it may become imperative to automate data entry. The alternates to manual data entry could be capturing data directly from another software such as SCADA or MES, bio-metric systems, attendance systems, bar code, QR Codes and other electro-mechanical instruments such as counters.

Production module is similar to other modules. It also has roles and access rights for people using it. It is important that role of different persons in production department are clearly defined and authorizations provided in ERP accordingly so as to improve accountability. Besides it, just like other modules, production module also needs masters such as machine codes, route codes, master of all Bill of Material, job cards etc. Processes for adding new records or editing masters need to be developed.

The ERP would be in the middle of scheme of things with Industry4.0 with all other technologies like internet of things, big data analytics, autonomous robots, augmented reality and simulations around it.

We would like to hear your experiences with Production module, either standalone or part of an ERP. Typically, maintenance and quality are out of purview of production module.

We welcome your feedback and suggestions for improvement. Please let us know if you would like more details on these modules. You can also reach out to us by writing to us on contact@mentorsunlocked.com